Te tiaki i ngā kiriata

Care of motion picture film

Read information on identifying and managing any motion picture film you may hold.

The materials and nature of motion picture film make them prone to deterioration and damage caused by incorrect storage conditions. This deterioration shows up as:

brittleness of the item

stickiness

‘bubbles’ on the surface

colour fading

silver mirroring — a metallic sheen that obscures parts of the image.

Odours are another sign of chemical breakdown. Poor handling and incorrect use of equipment can mechanically damage the film.

Read more information on how to store video and other magnetic materials.

Characteristics and risks of motion picture film

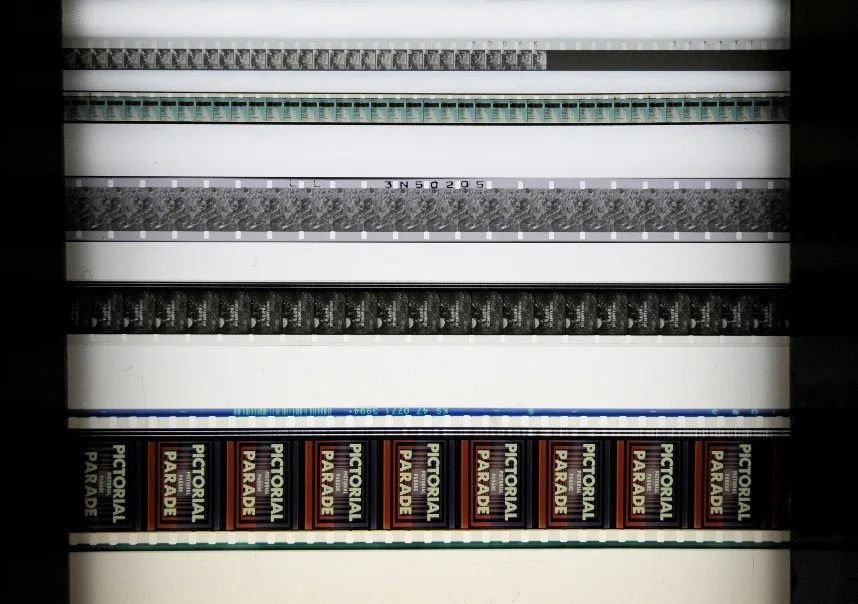

Film is generally stored in rolled form in either metal or plastic cans. Since its creation, many different gauges have been manufactured. But the most common formats are 8mm, Super 8, 16mm, Super 16 and 35mm. Images can be negative or positive, with or without sound. The soundtrack may be optical — such as a squiggly or banded line running along the edge of the film — or magnetic.

Film is made up of many layers, but it’s simplest to think of it as an image layer and a plastic supporting layer for the image to rest on. Early film had a cellulose nitrate supporting base. This evolved into the use of cellulose acetate bases and later a far more stable polyester support. In high humidity or high temperature storage conditions, the film will deteriorate faster, leading to the breakdown of cellulose nitrate and acetate bases. Cellulose acetate and polyester films are still available, but technology to read them is becoming obsolete which means they’re now rarely used.

The image bearing layer is made up of colour dyes, or in the case of black and white film, small silver particles. Early black and white films were sometimes hand-coloured or toned. Colour dyes are generally more unstable than black and white and prone to fading over time. The image will often appear a bright magenta as the blue and yellow dyes are usually the first to fade. In poor storage conditions black and white film can exhibit silver mirroring. The image is attached to the plastic by gelatin, which is a moisture absorbing substance. In storage environments with a relative humidity over 70%, there’s a strong risk of mould consuming the image bearing layer.

Types of plastic supports

Cellulose acetate was produced from the early 1910s to the present day. As concerns over the flammability of nitrate increased more people used acetate film, which was referred to as ‘safety film’.

Acetate will break down over time and this process is greatly sped up in high humidity conditions. As acetate decomposes it will let off acetic acid, commonly called ‘vinegar syndrome’. The support layer will shrink and become brittle, eventually causing the image and supporting layer to separate.

An earlier form of acetate support — diacetate — is known to produce a camphor or moth ball odour as it breaks down.

Cellulose nitrate was produced from the 1890s to the early 1950s. It’s classed as a hazardous substance (HSNO) 4.1.1.B. It’s a highly flammable solid and requires very strict storage conditions. If you suspect you have records on a nitrate support, contact us for advice on transferring or reformatting this material.

The black and white image on nitrate supports can fade and the support itself can discolour, taking on a yellowish or brown appearance. Nitrate film will decompose at a faster rate in high humidity conditions and may let off nitric acid and become sticky. As breakdown progresses, flammability becomes more of a risk.

Polyester was introduced as film support in 1955. It’s a far more stable material than nitrate or acetate so is less likely to break down.

How to identify film types

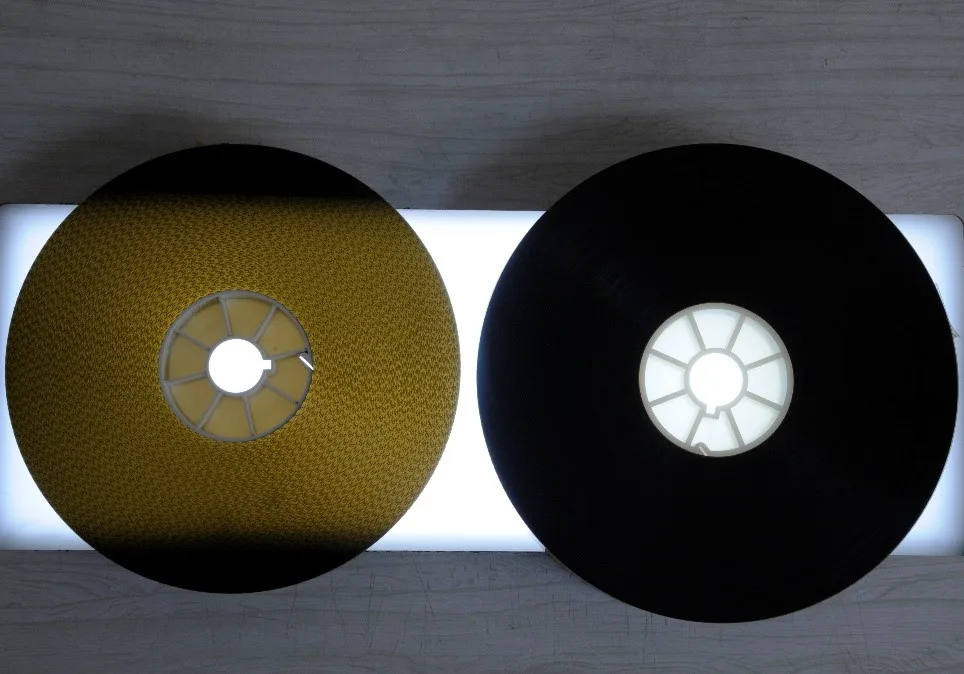

When viewed on a light box light, polyester film will appear translucent and acetate film will be opaque. Films with an acetate support will often be identified as ‘Safety Film’ along the edge. Smaller gauge films, for example, 8mm and 16mm, were only produced on acetate or polyester supports.

How to store and handle motion film

Use non-abrasive, non-shedding gloves when handling film. Oils from skin contact can permanently damage the image layer. Handle film by the edges.

Store film horizontally on film cores as shown in the image above, rather than on projector reels.

You should house the film in canisters such as polypropylene cans, to protect it from the external environment.

Store film in shade and away from direct sunlight.

Avoid placing magnetic sound film near magnetic devices.

Use archivally film splicing tape to repair film if necessary.

You should store the film in cool or cold, dry and stable environments to slow down the rate of decomposition. For example, 2 to 12 degrees, 30 to 50 percent relative humidity. Although polyester is a far more stable material, keep it in cool or cold conditions to extend its lifespan.

If there is no heating, ventilation and cooling system (HVAC) to reduce temperatures — or there are only small amounts of affected material — consider running a chest freezer for long term storage.

Note: There is a risk of condensation on the material if it's taken straight out of a freezer or low temperatures. To remove this risk, you must follow a staged acclimatisation procedure from freezer to room temperature. First step of this procedure is enclosing the material in a cool bag or placing in a room no more than 10 degrees warmer than the freezer for 24 hours. The next step is to move it into room temperature, still leaving it in the cool bag for a further 24 hours.

Consider transferring master or unique material to us.

Our film archives

We house film collections in cool, dry storage and have separate off-site facilities for nitrate film. We maintain an active preservation programme. This includes copying film on less stable supports such as nitrate and acetate to polyester film. Other activities focus on the reformatting of film by creating preservation and access copies by means of telecine and scanning. These files are preserved in our digital repository and made available to the public online.